Environmental

Stewardship

Our Approach

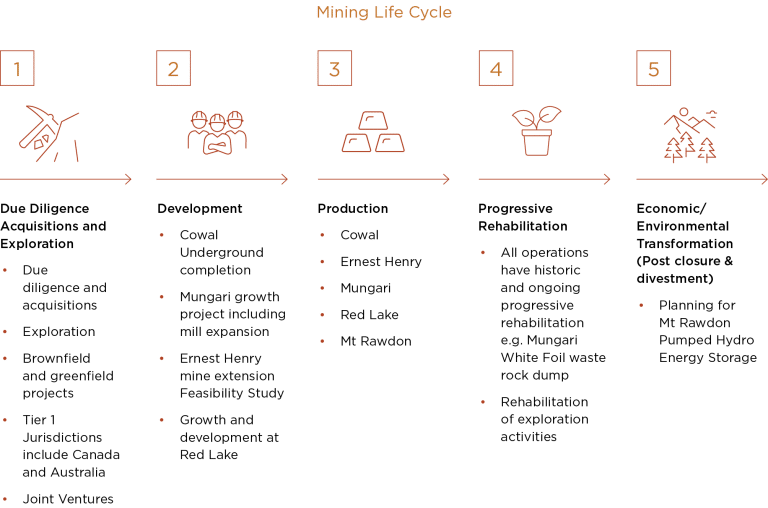

Environmental stewardship is a foundational element of Evolution’s Sustainability Strategy and is essential to maintaining our social licence and trust within the communities in which we operate. In accordance with the Sustainability and Strategic Planning Policy and associated Standards, we incorporate environmental management including climate change into all areas of

the business to manage risks, impacts and opportunities throughout the mine lifecycle. This includes integration into the due diligence and exploration processes. We operate beyond legal compliance through the Evolution Risk Management Framework to live our values and deliver against our social licence expectations.

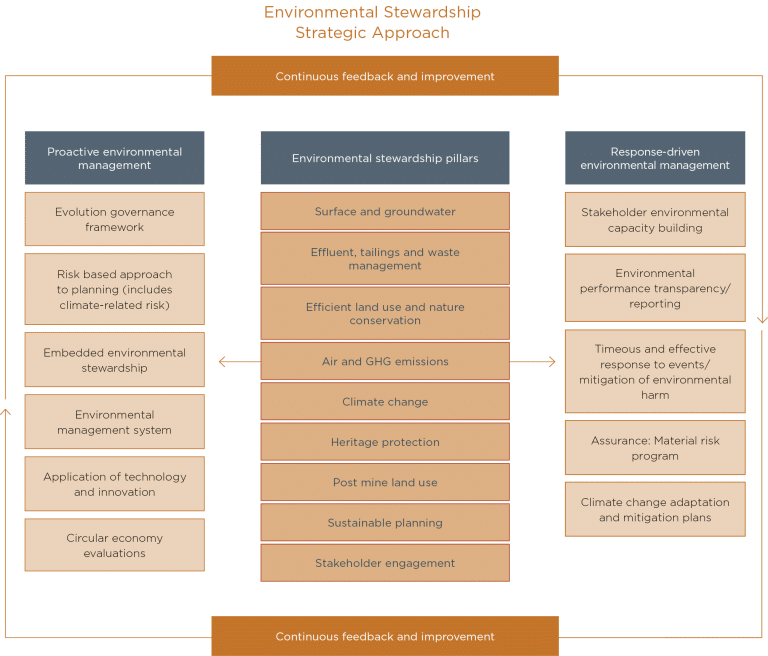

We strive for sustainable consumption and safe production at all operations to ensure we leave a positive legacy supporting the needs of present and future generations. Our strategic approach to environmental stewardship comprises proactive and consistent risk-based environmental management, including the consideration of risks related to climate change and the broader environmental footprint, underpinned by continuous feedback and improvement.

Being a responsible environmental steward is central to maintaining our social licence to operate. By supporting our people who work to protect the environment and improve biodiversity outcomes, we deliver long-term value to all stakeholders.

LAWRIE CONWAY

MANAGING DIRECTOR AND CHIEF EXECUTIVE OFFICER

During FY23, we have continued to:

• Strengthen environmental stewardship across operations through review and integration of our Sustainability Performance Standards and Strategic Planning Standards

• Build capability and environmental awareness through alignment with global standards and frameworks

• Address climate-related risks of water security to reduce raw water demand by minimising water use requirements in processes and maximising water reuse or recycling where possible

• Plan for and manage extreme weather events, for example Mt Rawdon’s unseasonal rainfall

• Monitor surface water, groundwater, land and nature to protect and enhance environmental values

• Assess and implement energy efficiency and greenhouse gas (GHG) emission reduction initiatives, partnerships and projects

• Monitor noise, vibration and air emissions to confirm the effectiveness of the mitigating measures for the protection and well being of the environment and local communities

• Follow strict protocols for storage, handling, labelling, and disposal of hazardous materials, including fuels, chemicals and wastes for the protection of the workforce, our communities and the environment

• Consult with and communicate to stakeholders including the local communities on mine planning, operations and post mine land use

Environmental Compliance

Management Approach

At the core of our approach to environmental compliance is the effective management of mining-related activities to protect cultural and environmental values, including the rights and interests of local communities. All our operations are subject to environmental regulation in

the various jurisdictions in which we operate through permitting, approvals and regulatory compliance requirements. Permit and licence provisions provide stringent requirements to support the health and safety of our communities and the environment.

All operations are required to maintain regular compliance monitoring and reporting to demonstrate conformity with current legal and other obligations, supported by assurance activity.

A uniform internal reporting system is implemented across all operations. All environmental events, including potential non-conformance to any licence provisions, are assessed according to their actual or potential environmental and/or regulatory consequence. Levels of environmental incidents are tracked based on factors such as spill volume, incident location (onsite or offsite), potential or actual environmental impacts and legal obligation, on a scale from Very Minor to Extreme in alignment with the Evolution RAM.

Performance

All operations retained a strong focus on environmental performance throughout FY23 with no material environmental incidents reported, and no significant (>US$10,000) fines paid related to environmental compliance. One moderate risk event occurred with an enforcement action issued to Mt Rawdon for a noncompliance associated with extended, unseasonal rainfall in late 2022. Other minor or very minor risk events occurring during FY23 were reported to the relevant government authority, as required, and agreed action taken where appropriate.